MR-24® Roof System

The hole of connection is pre-punched in plant to match factory-punched purlin and assure a proper alignment with roof panel. Meanwhile, the sealant and sealed strip used between panel connection has a long lifetime over 20 years. There is a nylon particle inside of sealant in case of extruding in the erection.

A high strength and aluminum alloy up-panel and down-strip will be jointed and pressed tightly, which makes wall panel can be lapped on the purlin, preventing panel from leakage due to walking and heavy snow load.

Water-proofing

MR-24® rib of roof panel is 70mm after rolling, rainwater is hard to overflow the peak.

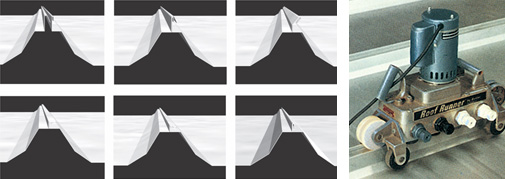

The MR-24® roof system is the only standing-seam roof system where the critical 180 degrees of the roof panel seam is mechanically field-rolled to complete a 360-degree Pittsburgh double-lock seam by roof runner 2 tons force is pressurized in the seal process and a tightest seam is created.

The MR-24® panel‘s first 180 degrees is rolled in factory. An imported sealant will be first infused into the seam in the plant, so the capillarity will not happen through the seam in the bad weather.